گیج های فشار از راه دور و گیج های فشار از راه دور - راه حل های نظارت صنعتی

به دنبال نظارت بر فشار از راه دور قابل اعتماد هستید؟ گیج های فشار خوانش از راه دور و گیج های فشار از راه دور با کیفیت بالا ما، خروجی های 4-20mA، RS485 را برای پمپ ها، HVAC و سیستم های صنعتی ارائه می دهند. دقیق، بادوام و آسان برای نصب.

گیج فشار خوانش از راه دور چیست؟

گیج فشار خوانش از راه دور، که اغلب گیج فشار از راه دور یا گیج انتقال از راه دور نامیده می شود، یک ابزار ضروری برای سیستم های نظارت و کنترل صنعتی مدرن است. بر خلاف گیج های صفحه محلی سنتی، اندازه گیری فشار فیزیکی را به یک سیگنال الکتریکی استاندارد (مانند 4-20mA یا 0-10V DC) یا یک سیگنال دیجیتال (مانند RS485) تبدیل می کند. این سیگنال را می توان از راه دور به یک مکان مرکزی - مانند PLC (کنترل کننده منطقی قابل برنامه ریزی)، سیستم SCADA یا صفحه نمایش اتاق کنترل - منتقل کرد و امکان نظارت در زمان واقعی، ثبت داده ها، اتوماسیون فرآیند و هشدارها را بدون نیاز به حضور فیزیکی پرسنل در نقطه اندازه گیری فراهم می کند.

چرا گیج های فشار از راه دور ما را انتخاب کنید؟

گیج های ما شکاف بین اندازه گیری مکانیکی قوی و کنترل دیجیتال مدرن را پر می کنند و قابلیت اطمینان را در جایی که بیشترین اهمیت را دارد ارائه می دهند.

- عملکرد دوگانه: یک صفحه نمایش آنالوگ محلی واضح برای تأیید در محل به علاوه یک خروجی سیگنال از راه دور پیوسته.

- خروجی های استاندارد صنعت: سازگار با تمام سیستم های کنترل اصلی از طریق 4-20mA (2 سیم)، 0-5/10V، RS485 Modbus و موارد دیگر.

- دوام استثنایی: ساخته شده با محفظه های فولادی ضد زنگ، لنزهای شیشه ایمنی و عناصر حسگر درجه صنعتی (لوله بوردون یا دیافراگم) برای مقاومت در برابر محیط های خشن، از جمله لرزش و ضربان.

- دقت بالا: کنترل و نظارت دقیق را با دقت های معمول ±0.5٪ تا ±1.0٪ از مقیاس کامل تضمین کنید.

- ادغام آسان: طراحی شده برای نصب و سیم کشی ساده، راه اندازی سریع سیستم شما.

ویژگی های کلیدی و مشخصات فنی

محدوده گیج های فشار از راه دور ما برای عملکرد در کاربردهای مختلف مهندسی شده است.

| ویژگی | مشخصات / توضیحات |

|---|

| نوع اندازه گیری | فشار گیج، فشار مطلق یا مرکب |

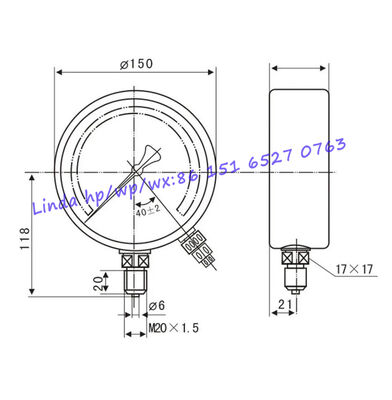

| صفحه نمایش محلی | صفحه نمایش آنالوگ 4 اینچی یا 6 اینچی (100 میلی متر یا 150 میلی متر) |

| خروجی سیگنال از راه دور | 4-20mA (2 سیم)، 0-5V، 0-10V، RS485 با Modbus RTU |

| محدوده فشار | از خلاء (0 تا -1 بار) تا فشار بالا (0 تا 1000 بار / 15000 psi) |

| کلاس دقت | 0.5٪ FS، 1.0٪ FS (استاندارد) |

| اتصال فرآیند | 1/4 اینچ NPT، 1/2 اینچ NPT، G1/2، M20x1.5 یا سایر استانداردهای بین المللی |

| جنس بدنه | فولاد ضد زنگ (316L یا 304) یا فنولیک مقاوم |

| پنجره | شیشه ایمنی تمپر شده یا پلی کربنات |

| رتبه بندی محیطی | IP65 (ضد گرد و غبار و محافظت شده در برابر جت های آب) |

کاربردهای رایج گیج های انتقال از راه دور

گیج های فشار خوانش از راه دور در کجا استفاده می شوند؟ در هر جایی که نیاز به نظارت بر فشار از راه دور یا ادغام آن در یک سیستم خودکار دارید.

گالری برنامه

- پمپ ها و کمپرسورهای صنعتی: نظارت بر فشار تخلیه/مکش برای عملکرد و ایمنی.

- سیستم های HVAC/R: نظارت بر فشار آب سرد، آب گرم و مبرد در ساختمان های بزرگ.

- صنایع فرآیندی (شیمیایی، نفت و گاز): برای خطوط لوله، مخازن و نظارت بر فشار راکتور در حلقه های کنترل بسیار مهم است.

- تصفیه آب و فاضلاب: نظارت بر فشار فیلتر، وضعیت پمپ و سطح مخزن.

- تولید برق: نظارت بر سیستم بخار، آب تغذیه و روغن کاری.

- تولید و اتوماسیون: کنترل سیستم هیدرولیک و پنوماتیک در خطوط تولید.

انتخاب مدل مناسب: راهنمای خروجی

انتخاب گیج فشار از راه دور صحیح به الزامات ورودی سیستم شما بستگی دارد.

- برای ماژول های ورودی آنالوگ PLC: گیج خروجی 4-20mA را انتخاب کنید. این رایج ترین استاندارد صنعتی مقاوم در برابر نویز برای انتقال از راه دور است.

- برای اتصال مستقیم کامپیوتر یا ثبت کننده داده: گیج خروجی RS485 Modbus را برای قابلیت شبکه چندگانه و یکپارچگی داده های دیجیتال انتخاب کنید.

- برای سیستم های کنترل ساده تر یا درایوهای سرعت متغیر (VFD): گیج خروجی 0-10V یک راه حل ساده و مقرون به صرفه است.

یادداشت های نصب و سیم کشی

- نصب: گیج را به صورت عمودی روی یک سطح یا پانل پایدار با استفاده از براکت ارائه شده نصب کنید. در صورت نیاز، اطمینان حاصل کنید که به راحتی قابل مشاهده است.

- اتصال فرآیند: از نوار درزگیر یا درزگیر رزوه مناسب روی رزوه های نر استفاده کنید. محکم ببندید تا از نشتی جلوگیری شود، اما از گشتاور بیش از حد خودداری کنید.

- اتصال الکتریکی: برای مدل های 4-20mA، دو سیم را به صورت سری با منبع تغذیه (معمولاً 12-24V DC) و ورودی PLC وصل کنید. قطبیت را رعایت کنید.

- راه اندازی: پس از روشن شدن، گیج سیگنالی را متناسب با فشار اندازه گیری شده (به عنوان مثال، 4mA = فشار صفر، 20mA = فشار مقیاس کامل) خروجی می دهد.

سوالات متداول: گیج های فشار از راه دور

س: تفاوت اصلی بین گیج فشار از راه دور و فرستنده فشار چیست؟

پاسخ: گیج فشار از راه دور دارای صفحه نمایش محلی و خروجی الکتریکی است. فرستنده فشار معمولاً صفحه نمایش محلی ندارد و یک دستگاه کوچکتر است که منحصراً بر تولید سیگنال خروجی متمرکز است. گیج های ما مزیت هر دو را ارائه می دهند.

س: حداکثر فاصله انتقال برای سیگنال 4-20mA چقدر است؟

پاسخ: با اندازه سیم مناسب، یک سیگنال 4-20mA می تواند با اطمینان بیش از 1000 متر یا بیشتر منتقل شود، زیرا یک سیگنال جریان است که در برابر افت ولتاژ مقاوم است.

س: آیا می توانید محدوده ها و خروجی های فشار سفارشی ارائه دهید؟

پاسخ: بله. ما در سفارشی سازی گیج ها برای محدوده های خاص، اتصالات فرآیند، خروجی های الکتریکی و لوگوهای صفحه نمایش تخصص داریم. با الزامات خود با ما تماس بگیرید.

آیا آماده اید تا نظارت بر فشار از راه دور قابل اعتماد را در سیستم خود ادغام کنید؟

سری محصولات دقیق ما را در زیر مرور کنید یا با تیم مهندسی ما تماس بگیرید تا یک مشاوره رایگان در مورد بهترین گیج فشار خوانش از راه دور برای برنامه خود دریافت کنید.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!